Select pipe friction Coefficient:

The pipe friction coefficient is a dimensionless number. The friction factor for laminar flow condition is a function of Reynolds number only, for turbulent flow it is also a function of the characteristics of the pipe wall.

Determine Pipe friction coefficient at laminar flow:

λ = 64 / Re

Where:

λ = Pipe Friction Coefficient

Re = Reynolds number

Note: Perfectly smooth pipes will have a roughness of zero.

Determine Pipe friction coefficient at turbulent flow (in the most cases) Colbrook Equation:

or

Where:

= Pipe Friction Coefficient

g = Acceleration of Gravity (9.8 m/s/s)

Re = Reynolds Number (unitless)

k = Absolute Roughness (mm)

D = Diameter of Pipe (m)

lg = Short for Log

The solutions to this calculation is plotted vs. the Reynolds number to create a Moody Chart.

Following table gives typical roughness values in millimeters for commonly used piping materials.

| Surface Material | Absolute Roughness Coefficient - k (mm) |

| Aluminum, Lead | 0.001 - 0.002 |

| Drawn Brass, Drawn Copper | 0.0015 |

| Aluminum, Lead | 0.001 - 0.002 |

| PVC, Plastic Pipes | 0.0015 |

| Fiberglass | 0.005 |

| Stainless steel | 0.015 |

| Steel commercial pipe | 0.045 - 0.09 |

| Stretched steel | 0.015 |

| Weld steel | 0.045 |

| Galvanized steel | 0.15 |

| Rusted steel | 0.15 - 4 |

| Riveted steel | 0.9 - 9 |

| New cast iron | 0.25 - 0.8 |

| Worn cast iron | 0.8 - 1.5 |

| Corroding cast iron | 1.5 - 2.5 |

| Asphalted cast iron | 0.012 |

| Galvanized iron | 0.015 |

| Smoothed cement | 0.3 |

| Ordinary concrete | 0.3 - 3 |

| Well planed wood | 0.18 - 0.9 |

| Ordinary wood | 5 |

Determine Pressure drop in circular pipes:

Where:

Δp = Pressure Drop (Pa or kg / m-s 2)

λ = Pipe Friction Coefficient

L = Length of Pipe (m)

D = Pipe Diameter (m)

p = Density (kg/m3)

ω = Flow Velocity (m/s2)

If you have valves, elbows and other elements along your pipe then you calculate the pressure drop with resistance coefficients specifically for the element. The resistance coefficients are in most cases found through practical tests and through vendor specification documents. If the resistance coefficient is known, than we can calculate the pressure drop for the element.

Where:

= Pressure Drop (kg/m2)

= Resistance Coefficient (determined by test or vendor specification)

p = Density (kg/m3)

ω = Flow Velocity

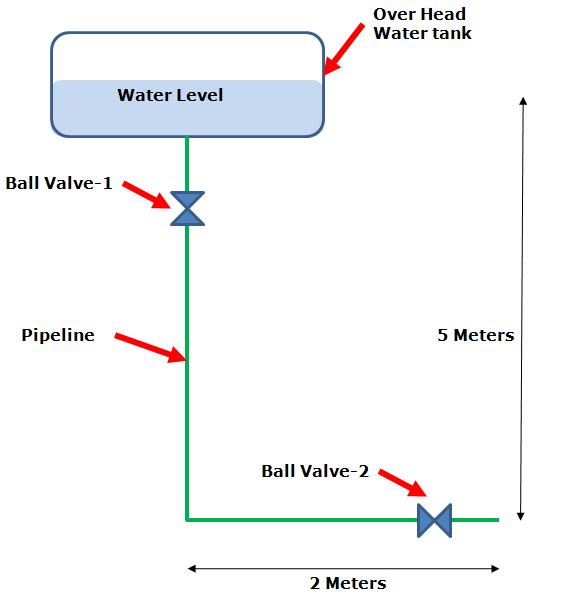

Pressure drop by gravity or vertical elevation

Where:

Δp = Pressure Drop (kg/m2)

p = Density (kg/m3)

g = Acceleration of Gravity (9.8 m/s/s)

ΔH = Vertical Elevation or Drop(m)

Pressure drop of gasses and vapor

Compressible fluids expands caused by pressure drops (friction) and the velocity will increase. Therefore is the pressure drop along the pipe not constant.

Where:

p1 = Pressure incoming (kg/m2)

T1 = Temperature incoming (°C)

p2 = Pressure leaving (kg/m2)

T2 = Temperature leaving (°C)

We set the pipe friction number as a constant and calculate it with the input-data. The temperature, which is used in the equation, is the average of entrance and exit of pipe.

Note: You can calculate gases as liquids, if the relative change of density is low (change ofdensity/density = 0.02).

© Copyright 2000 - 2019, by Engineers Edge, LLC www.engineersedge.com

All rights reserved

Disclaimer | Feedback

Advertising | Contact | Privacy Policy

Date/Time: